Low temperature evaporation is a recent development in the field of vacuum evaporation. In contrast with traditional vacuum evaporation, where you heat the materials to high temperatures, low temperature evaporation is ideal for evaporating materials with low evaporation temperatures such as most organic materials.

Recently there is an increase in interest in the use of Physical Vapor Deposition (PVD) methods for forming thin films of materials that have a relative low evaporation temperature. Examples include small-molecule compounds with properties useful for organic electronics applications such as OFETs, OLEDs and OPVs.

While traditional evaporation of metals normally takes place at temperatures >1000 ˚C, low temperature evaporation usually takes place at <600 ˚C. In addition to the differences in temperature, organic materials are extremely sensitive to temperature. A small temperature increase can make the difference between a zero deposition rate and ejection from the source of the entire load.

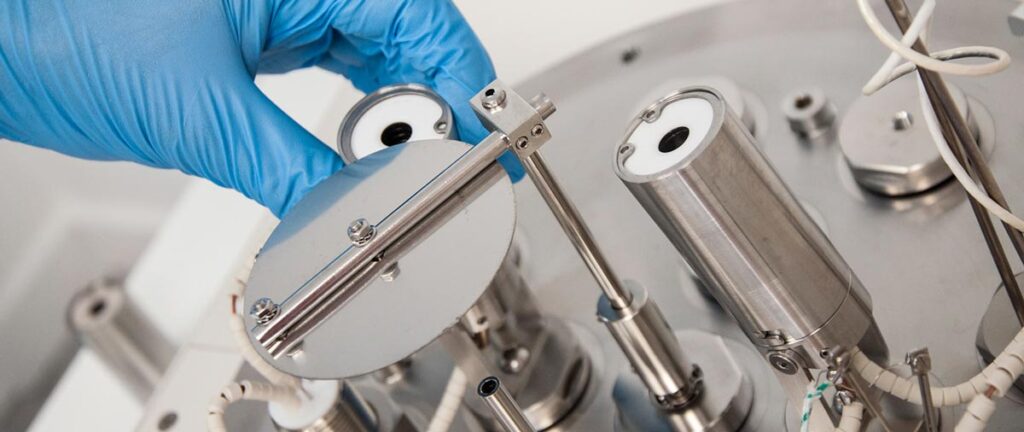

The secret source – Low temperature evaporation (LTE) cells

Given the above, the design of the low temperature evaporation sources are very different to those seen in standard thermal evaporation sources. In the low temperature evaporation cells the heating element and the material support are separated to allow for fine control of material heating power. This ensures that evaporating temperatures can be varied gradually, enabling precise variation of the deposition rate.

LTE sources are commonly used as part of a feedback loop, based on in-situ rate- and thickness measurements, as this provides for the best control performance. Like all evaporation techniques, LTE is a “line-of sight” technique. The Evaporated materials are moving in a straight line between the source and the substrate, as such, it provides highly anisotropic coatings useful for, among other, lift-off applications. However, in some cases, evaporants with very high vapor pressures, some isotropic nature may be seen due to high local pressures in the deposition plume.

Products

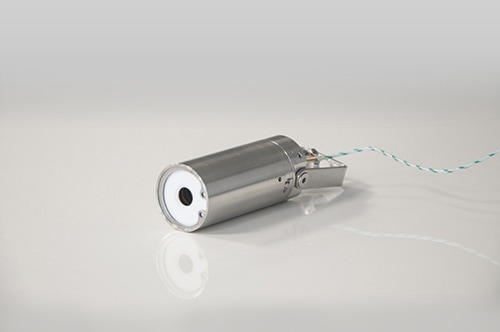

Flexible, modular PVD systems for high- quality R&D and pilot-scale production.

High-performance metals, organic evaporation in compact packages for benchtop location. Superior, efficient performance and ideal for OLED, OPV and OFET research.