Physical Vapor Deposition

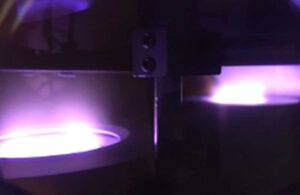

Physical Vapor Deposition (PVD) is a prominent thin-film coating technique used across industries like electronics, optics, and aerospace. In PVD, a solid material is vaporized within a vacuum environment. The vaporized atoms or molecules then travel and deposit onto a substrate, forming a thin film. PVD encompasses methods like sputtering and evaporation. Sputtering involves ion bombardment of a target material, releasing particles that coat the substrate. Evaporation relies on thermal energy to vaporize the source material for condensation onto the substrate. PVD offers benefits including precise thickness control, coating adherence to complex shapes, and material property enhancement. It’s pivotal for functional coatings, hardness improvement, optical enhancements, and conductivity modifications. PVD coatings are vital in semiconductors, solar cells, medical devices, and more, enabling tailored material characteristics.